Tech

How can AR VR and MR improve engineering instructions

With the rapid advancements in technology, the fields of engineering and construction are being transformed in unimaginable ways. Augmented Reality (AR), Virtual Reality (VR), and Mixed Reality (MR) have emerged as revolutionary technologies that have the potential to revolutionize the engineering industry. In this article, we will explore How AR, VR, and MR are Revolutionizing Engineering. The various applications and benefits of AR, VR, and MR in engineering and how they can enhance efficiency, safety, collaboration, and overall project outcomes.

1. Introduction

Engineering projects often involve complex designs, intricate systems, and extensive planning. Traditional design, simulation, and collaboration methods have limitations in effectively communicating ideas and visualizing the final product. This is where AR, VR, and MR technologies provide immersive and interactive experiences that bridge the gap between the digital and physical worlds.

2. Understanding Augmented, Virtual, and Mixed Reality

Augmented Reality (AR):

Augmented reality (AR) overlays digital information on the real world. This can be done using a variety of devices, such as smartphones, tablets, and headsets. AR is often used to provide information about the real world, such as directions, translations, or product information. For example, you can use an AR app to see the name of a plant or the directions to a restaurant overlaid on your view of the real world.

Virtual reality

Virtual reality (VR) creates a completely immersive experience that completely blocks out the real world. This is done using a headset that displays a virtual world and tracks the user’s head movements. VR is often used for gaming, training, and entertainment. For example, you can use a VR headset to play a video game that allows you to explore a virtual world or to train for a job that requires you to operate machinery

Mixed reality

Mixed reality (MR) is a combination of AR and VR. It overlays digital information on the real world, but it also allows the user to interact with the virtual objects. This is done using a headset that displays a virtual world and tracks the user’s head and hand movements. MR is still in its early stages of development, but it has the potential to be used for a wide variety of applications, such as training, design, and manufacturing.

Here is a table summarizing the key differences between AR, VR, and MR:

| Feature | Augmented reality (AR) | Virtual reality (VR) | Mixed reality (MR) |

|---|---|---|---|

| Definition | Overlays digital information on the real world | Creates a completely immersive experience that blocks out the real world | Combines AR and VR by overlaying digital information on the real world and allowing the user to interact with the virtual objects |

| Devices | Smartphones, tablets, headsets | Headsets | Headsets |

| Applications | Navigation, education, gaming, marketing | Gaming, training, entertainment | Training, design, manufacturing |

3. Augmented Reality in Engineering

AR technology offers several applications that can significantly improve various aspects of engineering projects.

3.1. Training and Simulation

AR can be used to create realistic training simulations, allowing engineers to practice complex tasks in a controlled environment. For example, maintenance personnel can use AR headsets to overlay step-by-step instructions onto equipment, reducing errors and improving efficiency.

3.2. Design and Visualization

AR enables engineers to visualize 3D models and designs in the real world. By overlaying digital models onto physical environments, engineers can better assess spatial relationships, identify potential clashes, and make informed design decisions.

3.3. Maintenance and Repair

AR can assist engineers in the maintenance and repair of complex systems. AR enhances efficiency and accuracy by overlaying relevant information onto equipment, such as live sensor data or repair instructions, reducing downtime and costs.

4. virtual Reality in Engineering

VR technology provides immersive experiences that have significant implications for the engineering field.

4.1. Design and Prototyping

VR allows engineers to create virtual prototypes, enabling them to explore and evaluate designs before physical production. This iterative process helps identify design flaws, optimize performance, and save time and resources.

4.2. Collaboration and Communication

VR facilitates collaboration among geographically dispersed teams. Engineers can meet virtually in a shared virtual environment, visualize and manipulate 3D models together, and communicate effectively, regardless of physical location.

4.3. Training and Education

VR offers realistic training experiences for engineers, enabling them to learn and practice complex procedures in a safe and controlled environment. VR simulations can simulate hazardous scenarios or provide hands-on training for operating specialized equipment.

5. Mixed Reality in Engineering

MR combines the benefits of both AR and VR technologies, unlocking new possibilities in the engineering sector.

5.1. Enhanced Visualization and Interaction

MR allows engineers to overlay contextual information onto the real world, enhancing their understanding and interaction with physical objects. For example, architects can visualize building plans on-site, making real-time adjustments and improving design accuracy.

5.2. Remote Assistance and Support

MR enables remote collaboration and assistance for engineering projects. Experts can provide real-time guidance and support to field technicians using MR headsets, reducing travel costs and increasing efficiency

5.3. Field Operations and Maintenance

MR can improve field operations by overlaying real-time data and instructions onto the engineer’s field of view. This technology enables engineers to access critical information hands-free, increasing productivity and reducing errors.

6. Benefits of AR, VR, and MR in Engineering

Integrating AR, VR, and MR technologies in engineering projects brings numerous benefits to the industry.

6.1. Increased Efficiency and Accuracy

AR, VR, and MR technologies streamline processes, reduce errors, and increase efficiency. Engineers can make informed decisions and execute tasks more precisely by providing real-time information, visualizations, and simulations.

6.2. Enhanced Safety

AR, VR, and MR technologies can improve safety by simulating hazardous scenarios, conducting virtual safety training, and enabling remote assistance. Engineers can identify and mitigate risks before they occur, minimizing accidents and injuries.

6.3. Improved Collaboration

These technologies enhance collaboration by enabling real-time communication, visualization, and shared experiences among team members. Geographically dispersed teams can work together seamlessly, improving coordination and project outcomes.

6.4. Cost Savings

Using AR, VR, and MR technologies can result in cost savings throughout the project lifecycle. Engineers can minimize project delays and expenses by reducing rework, optimizing designs, and improving communication.

7. Challenges and Limitations

While AR, VR, and MR technologies hold immense potential, they also face specific challenges and limitations.

7.1. Technical Limitations

AR, VR, and MR technologies require robust hardware and software infrastructure to deliver optimal experiences. The quality of visuals, tracking accuracy, and device limitations can impact the user experience and adoption rate.

7.2. Cost and Implementation Challenges

Implementing AR, VR, and MR technologies can be costly, especially for small and medium-sized engineering firms. Initial investments in hardware, software, and training may pose financial challenges, limiting widespread adoption.

7.3. User Acceptance and Training

Integrating new technologies often requires a learning curve and changes in work practices. Engineers and workers may need training and support to adapt to the latest tools, affecting the pace of adoption and user acceptance.

8. Future Outlook

The future of AR, VR, and MR in engineering is promising. As technology advances, we can expect more sophisticated applications and improved accessibility. Integrating artificial intelligence and machine learning will further enhance these technologies’ capabilities, revolutionizing engineering practices.

Conclusion

AR, VR, and MR technologies can transform the engineering industry by improving efficiency, safety, collaboration, and project outcomes. From design and visualization to training and maintenance, these technologies offer numerous benefits that can revolutionize engineering practices. However, challenges such as cost, implementation, and user acceptance must be addressed for widespread adoption. The engineering sector should embrace these technologies and harness their transformative power as we move forward.

10. FAQs

A1. While the adoption of these technologies is growing, they have yet to be widely used across the entire engineering industry. However, many companies recognize their potential and gradually incorporate it into their workflows.

A2. These technologies enable remote collaboration by providing shared virtual environments where team members can visualize and manipulate 3D models. This facilitates effective communication and enhances collaboration, regardless of geographical distances.

A3. Yes, by improving efficiency, minimizing errors, and optimizing designs, these technologies can help reduce project costs. They enable better decision-making, reduce rework, and enhance communication, resulting in cost savings.

A4. Yes, there are limitations, such as technical requirements, initial implementation costs, and the need for user training and acceptance. These factors can impact the widespread adoption and implementation of these technologies.

A5. The future looks promising, with advancements in technology and increasing affordability. We can expect more sophisticated applications, improved user experiences, and further integration with artificial intelligence and machine learning, revolutionizing engineering practices.

VR in engineering mechanics

In this field, experts can create 3D models of industrial machinery and use virtual reality to identify and resolve technical problems. Additionally, a study demonstrated the potential of VR apps for teaching mechanical engineering.

Tech

What are the 19 emerging technologies in 2024?

Introduction

As the world hurtles towards the year 2024, we find ourselves standing on the cusp of groundbreaking technological innovations that promise to reshape industries and the way we live. From artificial intelligence (AI) to quantum computing, the emerging technologies of 2023 are primed to revolutionize our lives in ways we could have only imagined before. In this article, we will explore the 19 most promising emerging technologies and provide links to resources where readers can delve deeper into each of these cutting-edge fields.

Artificial Intelligence: The Intelligent Revolution

Artificial intelligence (AI) is at the cutting edge of current innovation. Through its ability to simulate human intelligence, AI revolutionizes various sectors, from healthcare and finance to transportation and entertainment. Machine Learning, Deep Learning, and Neural Networks are LSI keywords.

AIs are learning from vast datasets and optimizing outcomes for real-world problems, propelling us toward an era of automation and intelligent decision-making.

Internet of Things (IoT): Connecting the Unconnected

The Internet of Things (IoT) seamlessly merges physical and digital realms, facilitating communication between devices. This interconnected network streamlines processes, enhancing efficiency and convenience. LSI Keywords: Smart Devices, Connectivity, IoT Ecosystem.

IoT’s transformative potential reaches into homes, industries, and smart cities, creating an unprecedented level of automation and data-driven insights.

Blockchain: Building Trust in a Decentralized World

Blockchain technology revolutionizes data storage and transactions through its decentralized and immutable nature. It ensures transparency, security, and trust in various applications, particularly in finance and supply chain management. LSI Keywords: Cryptocurrency, Smart Contracts, Distributed Ledger.

By removing intermediaries and ensuring tamper-proof records, blockchain paves the way for a trustless and efficient digital future.

Quantum Computing: Unleashing Exponential Processing Power

Quantum Computing pushes the boundaries of classical computing by leveraging quantum phenomena to perform complex calculations at an unimaginable speed. This breakthrough technology holds immense potential in solving previously insurmountable problems. LSI Keywords: Superposition, Entanglement, Quantum Bits.

Quantum computers can revolutionize cryptography, optimization, and scientific simulations, heralding a new era of computation.

5G Technology: Empowering a Hyperconnected World

The advent of 5G technology ushers in an era of ultra-fast, low-latency communication, transforming the way we interact with information and each other. LSI Keywords: Network Speed, IoT Connectivity, Enhanced Mobile Experience.

With increased data transfer rates and seamless connectivity, 5G enables a world of innovative applications, from augmented reality to remote surgery.

Nanotechnology: The Art of Manipulating the Minuscule

Nanotechnology deals with materials and devices on the nanoscale, unlocking a realm where atoms and molecules are harnessed to create groundbreaking advancements in medicine, electronics, and environmental sustainability. LSI Keywords: Nanomaterials, Nanomedicine, Nanoelectronics.

Nanotechnology enables us to engineer matter at the atomic level, leading to enhanced performance and novel applications.

Biotechnology: Shaping the Future of Life Sciences

Biotechnology harnesses biological systems and living organisms to develop products and technologies that advance healthcare, agriculture, and environmental conservation. LSI Keywords: Genetic Engineering, Biopharmaceuticals, Bioinformatics.

Biotechnology is transforming medicine, agriculture, and industry, promising a future of personalized treatments and sustainable practices.

Renewable Energy: Powering a Sustainable Planet

Renewable Energy sources, such as solar, wind, hydro, and geothermal, provide clean and sustainable alternatives to fossil fuels, reducing carbon emissions and mitigating climate change. LSI Keywords: Green Energy, Solar Power, Energy Transition.

As the world shifts toward renewable energy solutions, the potential for a greener and more sustainable future becomes attainable.

Autonomous Vehicles: Redefining Transportation

Autonomous vehicles are self-driving machines that leverage AI and sensor technologies to navigate without human intervention. LSI Keywords: Driverless Cars, Autonomous Drones, Mobility Revolution.

With the advent of autonomous vehicles, we envision a safer, more efficient transportation landscape, reshaping mobility as we know it.

Augmented Reality (AR) and Virtual Reality (VR): Blending Realities

AR and VR technologies blend the physical and digital worlds, offering immersive and interactive experiences in gaming, education, training, and entertainment. LSI Keywords: Mixed Reality, Immersive Technology, AR/VR Applications.

Augmented and Virtual Reality redefine the way we perceive reality, creating boundless opportunities for education, entertainment, and business.

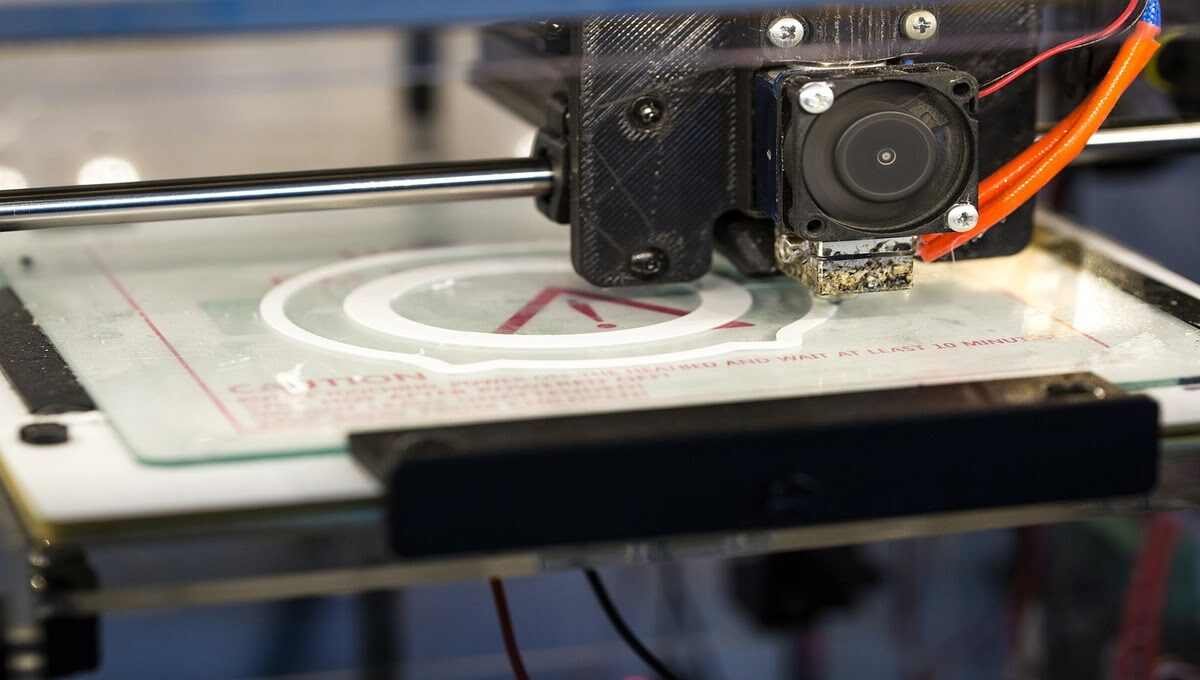

3D Printing: Using Additive Manufacturing to Its Full Potential

3D Printing, or Additive Manufacturing, constructs objects layer by layer from digital models, revolutionizing prototyping, manufacturing, and personalized product development. LSI Keywords: Rapid Prototyping, 3D Printing Materials, Customized Production.

With 3D Printing, we witness the democratization of manufacturing, enabling innovative designs and reduced waste.

Biometrics: The Future of Identity Verification

Biometrics employs unique biological traits, such as fingerprints and facial recognition, for secure and seamless identity verification in various applications, from smartphones to border control. LSI Keywords: Biometric Authentication, Identity Management, Security.

Biometric technologies are shaping a future where our physical attributes become our keys, enhancing security and convenience.

Space Exploration: Journeying Beyond the Horizons

Space Exploration endeavors to explore the cosmos, uncovering mysteries of the universe, and paving the way for potential colonization of other celestial bodies. LSI Keywords: Space Missions, Astronauts, Interplanetary Travel.

Through ambitious space missions, humanity embarks on an awe-inspiring quest to understand our place in the cosmos.

Nanomedicine: Revolutionizing Healthcare at the Nanoscale

Nanomedicine employs nanotechnology to diagnose, treat, and prevent diseases at the molecular level, offering targeted and precise medical interventions. LSI Keywords: Theranostics, Nanoparticles, Precision Medicine.

Nanomedicine holds the promise of highly effective and personalized treatments, revolutionizing the future of healthcare.

Edge Computing: Bringing Intelligence to the Edge

Edge Computing brings data processing closer to the source of data generation, enhancing real-time capabilities and reducing latency for various applications, such as IoT and AI. LSI Keywords: Edge Devices, Fog Computing, Low Latency.

With edge computing, we unlock a world of responsive and decentralized data processing, powering the internet of the future.

Wearable Technology: Integrating Tech into Everyday Life

Wearable Technology encompasses devices that seamlessly integrate into our daily lives, enhancing health monitoring, fitness tracking, communication, and productivity. LSI Keywords: Smartwatches, Fitness Trackers, Wearable Sensors.

Wearable technology is empowering individuals to monitor and optimize their well-being, fostering a more connected and health-conscious society.

Clean Meat: Pioneering Sustainable Protein Production

Clean Meat, also known as cultured or lab-grown meat, offers a sustainable and ethical alternative to traditional livestock farming, reducing environmental impact and animal suffering. LSI Keywords: Cell-Based Meat, Cultured Meat Industry, Animal-Free Protein.

Clean Meat revolutionizes the food industry, promoting ethical and environmentally friendly protein sources.

Swarm Robotics: The Power of Collective Intelligence

Swarm Robotics emulates the behavior of social insect colonies to create decentralized systems of coordinated robots that work collectively to achieve complex tasks. LSI Keywords: Collective Robotics, Swarm Intelligence, Decentralized Systems.

Swarm Robotics opens new possibilities for disaster response, exploration, and efficient industrial processes.

Human-Machine Interaction: Bridging the Gap

Human-Machine Interaction (HMI) focuses on creating intuitive and natural ways for humans to interact with machines, enabling seamless integration into our daily lives. LSI Keywords: User Interface, Voice Assistants, Gesture Recognition.

HMI strives to create technology that understands and adapts to human behaviors and preferences.

Energy Storage: Empowering Sustainable Power Management

Energy Storage technologies play a critical role in storing excess renewable energy, ensuring a stable and resilient power supply for communities and industries. LSI Keywords: Battery Storage, Grid-Scale Energy Storage, Energy Resilience.

As renewable energy adoption grows, efficient energy storage becomes paramount for a sustainable and reliable power grid.

Drones: Redefining Possibilities in the Sky

Drones, or Unmanned Aerial Vehicles (UAVs), offer a wide range of applications, from aerial photography and surveillance to delivery services and environmental monitoring. LSI Keywords: Drone Technology, UAV Applications, Aerial Data Collection.

Drones are transforming industries and optimizing operations by providing cost-effective and efficient solutions.

Artificial Neural Networks: Emulating the Human Brain

Artificial Neural Networks (ANNs) mimic the human brain’s neural connections to process complex information, driving advancements in AI and machine learning. LSI Keywords: Neural Network Models, Deep Learning Algorithms, Cognitive Computing.

Conclusion

The year 2023 brings with it an exciting wave of emerging technologies that will redefine how we live, work, and explore the world. From the boundless possibilities of AI to the enigmatic realm of quantum computing, each technology promises to unlock new frontiers. Embracing these innovations responsibly will be the key to shaping a future that benefits humanity as a whole.

FAQs

Where can I find online courses to learn more about these emerging technologies?

Many e-learning platforms, like Coursera, Udemy, and edX, offer courses on these technologies.

How will emerging technologies impact job opportunities in the future?

While some jobs may be automated, emerging technologies will create new job roles and opportunities in various industries.

Are there any ethical concerns related to AI and robotics?

Yes, ethical considerations such as privacy, bias, and responsible AI usage are crucial aspects of AI and robotics development.

Which industry will benefit the most from nanotechnology advancements?

Nanotechnology has broad applications, but healthcare and electronics are among the industries that will see significant benefits.

Will space technology lead to human colonization of other planets?

Space technology may pave the way for future space exploration and potential colonization, but it’s a complex and long-term goal.

Tech

The Most Promising Technology Trends of 2024

It’s 2024 and the world is a very different place. Scientists, researchers, and innovators have made incredible discoveries that are transforming our lives in ways we never thought possible. From advances in medicine to new technologies that make life easier and more efficient, here are some of the most exciting discoveries of 2024 so far:

2024 some interesting technology

1. Autonomous Vehicles:

Autonomous vehicles have been around for several years but continue to evolve. In 2023, these self-driving cars can be found on roads all over the world as they become an increasingly popular form of transportation for people who want a convenient way to get from point A to point B without having to drive themselves or rely on public transit options like buses or trains.

2 . Artificial Intelligence (AI):

AI has come a long way since its inception decades ago and it continues to improve every day, largely due advancements in machine learning algorithms which allow computers “think” more like humans do when making decisions based on data inputs provided by users or other sources online, offline, etc. This technology is being used across many industries, such ashealthcare,e where it helps doctors diagnose illnesses quicker than ever before; finance where automated trading systems help traders make better investments; and education where AI tutors can provide personalized instruction tailored specifically for each student’s needs; manufacturingprocesses,s which use robots instead of human labor power; and much more!

3 . 3D Printing Technology:

3D printing has revolutionized how we create physical objects from digital designs – whether those designs are created by hand using CAD software programs or generated automatically through algorithms programmed into printers themselves! In addition, this technology also allows us to access materials not easily available otherwise because they’re expensive, rare, hard to find, etc. All you need is your design file!

4 . Renewable Energy Sources:

By now renewable energy sources such as solar panels, wind turbines & hydroelectric dams have become ubiquitous sights globally providing clean electricity & reducing dependence upon burning fossil fuels cfuels,g air pollution & global warming effects at a large scale. With technological advancements leading towards cost-effectivesolutions,s both residential homes & industrial complexes alike can benefit greatly from these green energy alternatives!

5 . Virtual Reality (VR):

VR headsets were once considered toys only accessible by hardcore gamers, but today they’re becoming ubiquitous tools used everywhere, -from classrooms teaching students about ancient history cultures& civilizations via interactive simulations; to medical professionals training surgeons virtually before performing real surgeries; to businesses conducting virtual

6 Space Exploration:

Astronauts aboard International Space Station (ISS) were able to explore further into space by visiting Mars’ moons Phobic & Deimos, which allowed them unprecedented access to Martian surface features like craters; volcanoes;valleys,s etc., allowing us better understand its past geological history too! Additionally, robotic probes sent out during 2023 also revealed interesting facts about other bodies within the solar system, like Jupiter’s icy moon Europa, which may also hold clues about potential life there as well…

7 Gene Editing Technology:

The gene-editing tool CRISPR-Cas9 was improved upon this year so it could be used even more accurately when targeting specific genes responsible for certain diseases/disorders – allowing researchers to selectively alter genetic material inside cells without causing any haelsewhere, r,e thereby potentially curing some incurable conditions once thought to impossible!

8 Quantum Computing:

Researchers have created powerful computers that use quantum mechanics principles instead of traditional ones, like logic gates or transistors, to process information faster than ever before—up to millions of times more quickly! This technology could revolutionize computing power across all sectors, including medicine research & development (R&D), financial services & banking operations, etc., making them much more efficient than before with no need for additional hardware resources required at all!

Frequently Asked Questions (FAQs)

How is technology changing the way we live and work?

Technology is changing the way we live and work in many ways. For example, AI is being used to automate tasks, VR and AR are being used for training and education, blockchain is being used to create secure and transparent transactions, and quantum computing is being used to develop new drugs and materials.

How can we prepare for the future of technology?

We can prepare for the future of technology by:

-Learning about new technologies

-Developing skills in areas that are likely to be in demand

-Being aware of the potential risks of new technologies

-Being critical consumers of technology

-Advocating for policies that protect our privacy and security

What does the future of technology look like?

The future of technology is full of possibilities. We can expect to see continued advances in AI, VR, AR, blockchain, quantum computing, 5G, edge computing, and the IoT. These technologies have the potential to transform our lives in ways that we can’t even imagine.What does the future of technology look like?

The future of technology is full of possibilities. We can expect to see continued advances in AI, VR, AR, blockchain, quantum computing, 5G, edge computing, and the IoT. These technologies have the potential to transform our lives in ways that we can’t even imagine.

Tech

Concept of (AR) Augmented reality Technology and its uses

Augmented reality (AR) technology has revolutionized the way we interact with the digital world, bridging the gap between the virtual and the real. By overlaying computer-generated images onto the real world, AR enhances our perception and provides unique experiences across various industries. In this article, we will delve into the concept of AR (augmented reality), explore its uses in different fields, and examine the potential it holds for the future.

Introduction to Augmented Reality (AR)

Augmented Reality is a technology that blends digital content with the real world, creating an enhanced and interactive user experience. Unlike Virtual Reality (VR), which immerses the user in a completely simulated environment, AR overlays virtual elements onto the natural environment, allowing users to interact with both.

Entertainment and Gaming

AR has significantly impacted the entertainment and gaming industries. With the rise of mobile AR applications, users can engage in immersive experiences through smartphones or AR headsets. From popular games like Pokémon Go to interactive storytelling experiences, AR has opened up new avenues for entertainment.

Education and Training

In the realm of education and training, AR has transformed the learning experience. It offers interactive visualizations, 3D models, and simulations that make complex concepts more tangible and engaging. AR can be used to provide virtual field trips, anatomy visualizations, historical reenactments, and much more, enhancing student engagement and knowledge retention.

AR in Healthcare

The healthcare industry has embraced AR technology to improve patient care, medical training, and surgery planning. Surgeons can use AR to overlay patient data, such as medical images or real-time vitals, directly onto their field of view, enabling more precise and efficient procedures. AR also aids in medical education, allowing students to practice surgical techniques in a virtual environment.

Architecture and Design

Architects and designers utilize AR to visualize and present their projects more effectively. With AR, clients can experience virtual walkthroughs of architectural designs, explore the space, and make informed decisions before construction begins. AR also assists interior design by overlaying virtual furniture and decor onto natural spaces, allowing users to preview designs before implementation.

Retail and E-Commerce

AR is reshaping the retail and e-commerce landscape by offering immersive shopping experiences. Customers can try on virtual clothing, visualize furniture in their homes, or test makeup products using AR applications. This technology enhances customer engagement, reduces returns, and boosts online sales by accurately representing products.

Manufacturing and Engineering

AR finds practical applications in manufacturing and engineering processes. By overlaying digital information onto real-world objects, AR guides workers through complex assembly tasks, reducing errors and improving efficiency. AR also enables engineers to visualize and test designs in real time, facilitating rapid prototyping and streamlining the product development cycle.

Tourism and Travel

The tourism and travel industry has embraced AR to enhance visitors’ experiences and provide interactive guidance. AR-powered mobile applications offer virtual tour guides, historical information overlays, and augmented maps, enriching the exploration of landmarks and tourist destinations. AR also enables travelers to access real-time translations and reviews, making their journeys more convenient and immersive.

Marketing and Advertising

AR has transformed marketing and advertising strategies by adding interactive elements to campaigns. Brands can create AR experiences that allow customers to try products virtually, visualize advertisements in their surroundings, or participate in engaging storytelling campaigns. This technology captivates audiences, drives brand engagement, and fosters memorable experiences.

AR in Sports

Sports enthusiasts can enjoy augmented experiences through AR technology. AR applications can provide real-time data overlays during live games, enhancing viewers’ understanding of the match. Additionally, AR can assist athletes in training by giving performance analytics and visualizing techniques, leading to improved skills and performance.

AR Challenges and Future Developments

While AR has made significant advancements, challenges remain to be addressed. Technical hurdles like accurate tracking and real-time rendering need further improvement for seamless AR experiences. Privacy and data security concerns also require attention to ensure user trust and protection. However, with ongoing research and development, the future of AR looks promising, with potential advancements in wearable AR devices, holographic projections, and more.

Other uses of AR:

- Navigation: AR can be used to provide turn-by-turn navigation instructions or to display information about local businesses and landmarks.

- Tools and measurement: AR can be used to provide users with virtual tools or to measure distances and angles in the real world.

- Military: AR can be used to provide soldiers with information about their surroundings or to help them train for combat.

- Archaeology: AR can be used to help archaeologists reconstruct and visualize ancient sites.

AR technology is still in its early stages of development, but it has the potential to revolutionize the way we interact with the world around us. As AR devices become more affordable and accessible, we can expect to see even more innovative and groundbreaking uses for AR technology in the years to come.

Conclusion

Augmented Reality technology has transformed multiple industries, from entertainment and education to healthcare and retail. Its ability to blend the real and virtual worlds opens up possibilities for enhanced user experiences. As AR continues to evolve, we can expect even more exciting applications and advancements in the future.

Frequently Asked Questions (FAQs)

A1: While virtual reality creates a fully simulated environment, augmented reality overlays virtual elements onto the real world, enhancing the user’s perception without completely replacing it.

A2: Pokémon Go, Harry Potter: Wizards Unite, and Minecraft Earth are popular AR gaming applications that have gained widespread popularity.

A3: AR is increasingly used in industrial activity to guide workers through complex tasks, improving efficiency and reducing errors.

A4: No, AR technology can be experienced through smartphones, tablets, AR headsets, and other wearable devices.

A5: The future of AR holds great potential, with advancements in wearable AR devices, holographic projections, and seamless integration with everyday life.

5G2 years ago

5G2 years agoHow 5G Technology Will Revolutionize Our Lives and Work

Tech5 months ago

Tech5 months ago3d Printer Technology (Application) (History) And (Types)

5G2 months ago

5G2 months agoWhat is the difference between 5G and 5G Plus?

Computer1 year ago

Computer1 year ago“Bleeping Computer: Your Ultimate Guide to Cybersecurity”

5G1 year ago

5G1 year agoDifference between 5G nsa and 5G sa

5G1 year ago

5G1 year agoHow does 5g work on iPhone?

5G1 year ago

5G1 year agoThe Future of 5G Technology : Revolutionizing Connectivity

Tech1 year ago

Tech1 year agoExplain How Technology Has Affected People’s Activity Levels

fawahmad

February 25, 2023 at 2:16 pm

amazing blog